| |

| K700S FELDER PANEL SAW |

| |

| |

|

| |

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Main Saw Motor power: |

5.5HP |

| |

|

| Max. Saw blade diameter: |

315mm |

| |

|

| Cutting height at 90°: |

104mm |

| |

|

| Main Saw Speed: |

4800RPM |

| |

|

| Scoring Saw Motor Power: |

1.5HP |

| |

|

| Scoring Saw diameter: |

100mm |

| |

|

| Scoring Saw Speed: |

10000RPM |

| |

|

| Sliding table guiding system: |

“X-Roll” |

| |

|

| Tilt Segment: |

“Easy Glide” |

| |

|

| Sliding table length: |

3200mm |

| |

|

| Rip table capacity: |

800mm |

| |

|

| Crosscut fence length: |

2600mm |

| |

|

| Machine Weight: |

730Kg |

| |

|

| Machine Dimension: |

890x3700x6780mm |

|

| |

| 6 Year Guarantee on both Easy-Glide and X-Roll systems |

| |

| |

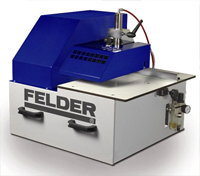

G500

FELDER THROUGH FEED EDGE BANDER |

| |

| |

|

| |

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Power Required: |

6.5HP |

| |

|

| Tape Thickness: |

0.4 – 3.0 mm coiled edges, 0.4 – 5.0 mm solid strips |

| |

|

| Work piece Thickness: |

8 – 60 mm |

| |

|

| Minimum Work piece Size: |

140mm Length x 70mm Width |

| |

|

| Feed Speed: |

11 m/min by heavy duty chain driven conveyor |

| |

|

| Glue Pot: |

2 kg capacity located below the glue |

| |

|

| Pressure Section: |

1 large steel roller, 2 conical steel rollers |

| |

|

| End Trimming Unit: |

1 motor, 0.27 kW, 12,000 rpm, Ø 100, 24 teeth, runs at 45°

|

| |

|

| Top and bottom trimming Unit: |

2 motors, each 0.5 kW, 12,000 rpm, Radius, flush and bevel trimming |

| |

|

| Radius scraping Unit: |

Removes any chatter marks from the Radius, leaving a perfect finish |

| |

|

| Glue Scraping Unit: |

For perfectly finished edging with no glue residue |

| |

|

| Buffing Unit: |

2 motors, 0.9 kW, 1400 rpm equipped with large textile wheels |

| |

|

| Required pneumatic pressure: |

6-8 Bar |

| |

|

| Machine Dimension: |

1550x3200x1100 mm(1370mm Max) |

| |

|

| Machine Weight: |

750 kg |

|

| |

| |

G580

FELDER THROUGH FEED EDGE BANDER |

| |

| |

|

| |

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Power Required: |

6.5 HP |

| |

|

| Tape Thickness: |

.4 – 3.0 mm coiled edges, 0.4 – 5.0 mm solid strips |

| |

|

| Work piece Thickness: |

8 – 45 mm |

| |

|

| Minimum Work piece Size: |

140mm Length x 70mm Width

|

| |

|

| Feed Speed: |

11 m/min by heavy duty chain driven Conveyor |

| |

|

| Pre-milling Unit: |

2 x Symmetrical Diamond V Cut milling unit. |

| |

|

| Glue Pot: |

2 kg capacity with Teflon coating |

| |

|

| Pressure Section: |

880 mm |

| |

|

| End Trimming Unit |

1 motor, 0.27 kW, 12,000 rpm, runs at 45° |

| |

|

| Top and bottom trimming Unit: |

2 motors, each 0.5 kW, 12,000 rpm, radius, flush and bevel trimming |

| |

|

| Corner Rounding unit: |

Soft/Post form work pieces max height 45mm. |

| |

|

| Radius scraping Unit: |

Removes any chatter marks from the radius, leaving a perfect finish |

| |

|

| Glue Scraping Unit: |

For perfectly finished edging with no glue residue |

| |

|

| Buffing Unit: |

2 motors, 0.9 kW, 1400 rpm equipped with large textile wheels |

| |

|

| Required pneumatic pressure: |

6-8 Bar |

| |

|

| Machine Dimension: |

2300x4520x1500 mm |

| |

|

| Machine Weight: |

1050KG |

|

| |

| |

| |

FD921

FELDER SINGLE HEAD MULTI BORING |

| |

| |

|

| |

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Number of Spindles: |

21 |

| |

|

| Distance between axis of drills: |

32 mm |

| |

|

| Distance between first and last drill: |

640 mm |

| |

|

| Max drilling depth: |

70 mm |

| |

|

| Ø of the drill shaft: |

10 mm |

| |

|

| Quick lock chucks: |

5 |

| |

|

| Max work piece size: |

850 x 3200 mm |

| |

|

| Working height: |

880 mm |

| |

|

| Dimension of machine table: |

900 x 340 mm |

| |

|

| No. of pneumatic hold-downs: |

2 |

| |

|

| Aluminum fence 1500 mm with 2 stops: |

2 |

| |

|

| Adjustable side-fence with lenses: |

2 |

| |

|

| Motor Power: |

2HP |

| |

|

| Motor speed at 50 Hz: |

2800 rpm |

| |

|

| Required pneumatic pressure: |

6-8 Bar |

| |

|

| Machine Dimension: |

890x895x1050 mm |

|

| |

| |

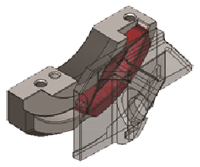

F700Z

FELDER SPINDLE MOULDER |

| |

| |

|

| |

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Motor power: |

5.5 HP |

| |

|

| Sliding table guiding system: |

“X-Roll” |

| |

|

| Tilt Segment: |

“Easy Glide” |

| |

|

| Sliding Table Length: |

1000mm standard |

| |

|

| Cast Iron table dimensions: |

850 x 500mm |

| |

|

| Spindle speeds RPM: |

3500/6500/8000/1000 |

| |

|

| Spindle tilt range: |

0–45 degrees backwards |

| |

|

| Spindle Diameter: |

30mm (Standard) |

| |

|

| Spindle Useable Height: |

115mm (Standard) |

| |

|

| Table opening: |

230 mm |

| |

|

| Power transfer: |

Poly V-belt |

| |

|

| Fence Plates: |

400mm |

| |

|

| Machine Weight: |

450Kg |

| |

|

| Machine Dimension: |

890x895x1050 mm |

|

| |

| 6 Year Guarantee on both Easy-Glide and X-Roll systems |

| |

| |

F3

HAMMER SPINDLE MOULDER |

| |

| |

|

| |

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Motor power: |

5.5 HP |

| |

|

| Sliding table guiding system: |

“Ball Bearing” |

| |

|

| Sliding Table Length: |

800mm standard |

| |

|

| Cast Iron table dimensions: |

950 x 350mm |

| |

|

| Spindle speeds RPM: |

3500/6500/8000/10000 |

| |

|

| Spindle tilt range: |

0–45 degrees backwards |

| |

|

| Spindle Diameter: |

30mm (Standard) |

| |

|

| Spindle Useable Height: |

100mm (Standard) |

| |

|

| Table opening: |

220 mm |

| |

|

| Power transfer: |

Poly V-belt |

| |

|

| Machine Weight: |

350Kg |

|

| |

| |

ERM 1050

FELDER CORNER ROUNDING MACHINE |

| |

| |

|

| |

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Motor performance: |

0.37kW |

| |

|

| Air Pressure driven: |

Yes |

| |

|

| Min/max thickness of workpiece: |

10/50 mm |

| |

|

| Min/max edge thickness: |

2/3 mm |

| |

|

| Blade rotation speed RPM: |

24,000 |

| |

|

| Operating Pressure: |

6-8 Bar |

| |

|

| Machine Weight: |

100Kg |

| |

|

| Machine Dimension: |

780 x 720 mm |

|

| |

| |

D951

FELDER THICKNESSER |

| |

| |

|

| |

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Motor power: |

7.5 HP |

| |

|

| Cutterblock: |

4-knife |

| |

|

| Thicknesser bed width: |

504 mm |

| |

|

| Thicknesser bed length: |

900 mm |

| |

|

| Thicknessing height: |

4 - 254 mm |

| |

|

| Variable speed adjustment: |

4 – 16 m/min |

| |

|

| Machine Weight: |

650Kg |

| |

|

| Machine Dimension: |

1082x950x1050mm |

|

| |